This is a crucial decision that shapes your business capabilities and profitability. The choice isn’t about which is universally better, but which mechanics of material handling best serve your target market. Let’s break it down.

Contents

Core Distinction: The Fundamental Difference

The difference is in the name:

- Flatbed UV Printers have a fixed, flat vacuum table that holds rigid sheets in place.

- Roll-to-Roll (R2R) UV Printers use a system of rollers to feed and rewind flexible media through the machine.

This single mechanical difference dictates everything they can produce.

Direct Comparison Table

| Decision Factor | Flatbed UV Printer | Roll-to-Roll (R2R) UV Printer |

|---|---|---|

| Primary Media | Rigid, flat substrates: Acrylic, wood, aluminum, glass, PVC sheets, foam board, etc. | Flexible, roll-based media: Vinyl, banner mesh, canvas, paper, textile, adhesive films, etc. |

| Key Workflow | Manual loading/unloading of individual sheets. Often requires “nesting” multiple items. | Automated continuous feed. Can print long, uninterrupted jobs unattended. |

| Typical Applications | Signage, custom gifts, industrial panels, phone cases, point-of-sale displays. | Vehicle wraps, wall murals, soft signage banners, floor graphics, window graphics, long posters. |

| Media Efficiency | Can lead to waste if sheet isn’t fully utilized (requires smart nesting). | Highly efficient for long runs; only uses the media needed for the print length. |

| Labor Intensity | Higher per job (handling individual sheets). | Lower for long runs (once set up, it runs automatically). |

| Best For Business Focus | Businesses centered on products made from rigid materials. | Businesses centered on large-format graphics and installations on flexible materials. |

Hybrid Printers: The Third (and Popular) Option

A Hybrid UV Printer combines both mechanisms into one machine. It features a movable or lowerable flatbed that allows a roll-to-roll system to pass over it.

- Function: Acts as a true flatbed for rigid sheets and as a roll-to-roll for flexible media.

- ROI Logic: It’s the ultimate versatile machine. While its upfront cost is higher than a comparable flatbed or R2R machine, it prevents you from turning away work. For a full-service shop, one hybrid can replace two dedicated machines.

How to Choose: A Business-Focused Guide

Ask yourself these questions to find the best fit:

Choose a FLATBED UV Printer if:

- Your product catalog or client requests are overwhelmingly (>80%) rigid items.

- You specialize in thick or oddly shaped objects (though height is limited by the printer’s Z-axis).

- Your priority is maximum quality and durability on hard surfaces for products like awards, signage, or decorative tiles.

Choose a ROLL-TO-ROLL UV Printer if:

- Your core business is banners, vehicle graphics, wall coverings, or floor graphics.

- You frequently need prints that are longer than standard sheet sizes (e.g., over 10 ft / 3 m).

- Automation and unattended printing are critical for your production volume on flexible materials.

Choose a HYBRID UV Printer if:

- You are a full-service print shop or marketing services provider with diverse client needs.

- You want the strategic flexibility to pivot between markets (e.g., from indoor signs to vehicle wraps) without a new capital investment.

- You frequently get jobs that require both rigid and flexible components (e.g., a trade show booth with a rigid backwall and a banner).

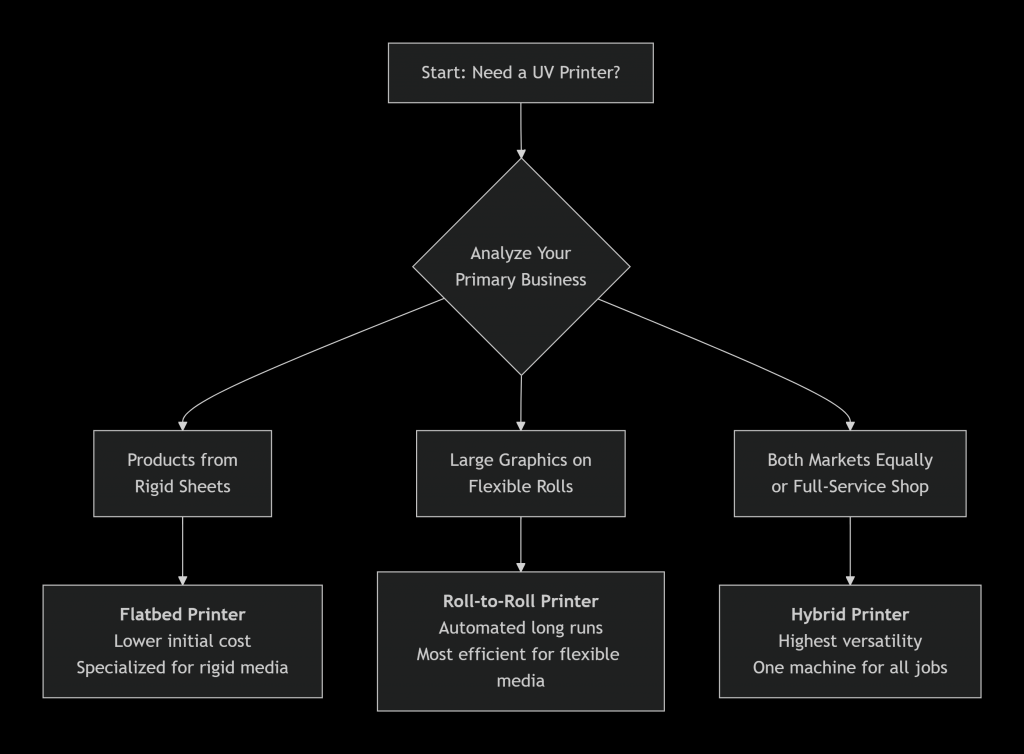

Visual Decision Pathway

Cost & Practical Considerations

| Consideration | Flatbed | Roll-to-Roll | Hybrid |

|---|---|---|---|

| Initial Purchase Price | Moderate | Moderate | Highest (for comparable print width) |

| Space Required | Machine footprint + sheet storage. | Machine length + roll storage. | Largest footprint (needs space for roll system). |

| Skill/Operational Complexity | Moderate. Focus on substrate handling and nesting. | Moderate. Focus on media tracking, tension, and weeding. | Highest. Must master two different media handling systems. |

| Hidden Cost Factor | Material waste from sheet optimization. | Media roll storage and handling. | Higher maintenance complexity and potential for more costly repairs. |

Final Recommendation

There is no single right answer. The choice is strategic:

- Specialize for Efficiency & Margins: If your market is clearly defined, choose the dedicated machine (Flatbed or R2R). You’ll get a faster ROI by not paying for capabilities you don’t use.

- Versatile for Growth & Client Retention: If you serve diverse clients or want to future-proof, the Hybrid is worth the premium. It turns “we can’t do that” into “yes, we can.”

Next Step: Before contacting suppliers, document your last 6 months of projects (or ideal projects). Categorize them by required material type (rigid sheet vs. flexible roll). The resulting percentage will give you a data-driven answer and make you a more informed buyer.