As UV DTF (Direct-to-Film) technology continues to mature, it is becoming a core production tool for commercial print shops, promotional product suppliers, signage companies, and custom merchandise businesses. Moving into 2026, UV DTF printers are no longer experimental equipment—they are revenue-generating assets that must deliver stability, speed, and consistent output.

However, many buyers still struggle with the same challenges: unreliable white ink performance, hidden maintenance costs, unclear ROI, and machines that look good on paper but fail under real production pressure. This article analyzes the real business pain points, provides data-driven insights, and offers a practical evaluation of commercial UV DTF printers—including a clear perspective on the Dowin GT Series UV DTF.

Contents

What Businesses Actually Need from a UV DTF Printer in 2026

Before comparing models, it’s critical to define what “commercial-grade” really means in 2026.

1. Consistent Print Quality (Not Just High Resolution)

Most UV DTF printers advertise high DPI numbers, but print consistency over time matters more than peak resolution. In real production environments, issues such as uneven white ink layers, banding, and color drift cause reprints and wasted material.

From user feedback and industry discussions, over 60% of UV DTF quality complaints are related to white ink instability and curing inconsistency—not design errors.

Key requirement: Stable white ink circulation, accurate layering (CMYK + White + Varnish if applicable), and reliable UV curing.

2. True Substrate Flexibility

A commercial UV DTF printer should reliably support:

- PET transfer film

- Plastic, acrylic, metal, glass, wood

- Irregular or curved surfaces (via transfer application)

UV DTF’s core advantage is its ability to produce high-adhesion decals without heat pressing, opening opportunities in labels, signage, customized consumer goods, and industrial marking.

If a printer only works well on film but struggles with adhesion or finish quality on hard materials, it limits your product range and revenue potential.

3. Throughput and Workflow Efficiency

For businesses, speed is not just print speed—it is jobs completed per day.

Key productivity factors include:

- Fast UV curing (no drying delay)

- Stable roll-to-roll or sheet handling

- Minimal manual intervention

- Low failure rate during long runs

A slow but stable printer often outperforms a fast but unreliable one when evaluated by daily output and labor cost.

4. Maintenance, Downtime, and Support Reality

One of the biggest buyer pain points is unexpected downtime.

Common issues reported by commercial users:

- White ink sedimentation after idle time

- Clogged printheads due to poor circulation

- Inconsistent after-sales support

- High cost or slow delivery of spare parts

Downtime is more expensive than hardware. Even one lost production day per month can erase the price advantage of a cheaper machine.

5. Total Cost of Ownership (TCO)

The real cost of a UV DTF printer includes:

- Ink consumption

- Film and consumables

- Replacement parts

- Maintenance labor

- Production downtime

In many cases, a machine with a 10–15% higher purchase price but better stability and support results in a lower total cost within 12–18 months.

Best Commercial UV DTF Printer Categories for 2026

Rather than listing brands blindly, it’s more useful to evaluate printers by commercial positioning.

All-in-One A3 UV DTF Printers

Best for Small to Medium Businesses

This category offers the most balanced entry into commercial UV DTF production.

Why it works:

- Integrated printing and UV curing

- Compact footprint

- Suitable for apparel transfers, labels, decals, and small signage

- Lower operational complexity

Business insight:

For most print shops transitioning from traditional DTF or vinyl, A3 all-in-one UV DTF printers deliver the fastest ROI with manageable risk.

Mid-Format and Roll-to-Roll UV DTF Printers

Best for Volume-Oriented Shops

Advantages include:

- Higher throughput

- Ability to gang multiple designs

- Reduced labor cost per unit

Risk to consider:

If your order volume is inconsistent, oversized machines often run under capacity, turning capital investment into idle equipment.

High-Finish UV DTF Printers (Varnish / Texture Effects)

Best for Premium Products

These systems focus on:

- Gloss or textured finishes

- Branding, luxury labels, decorative decals

Reality check:

Special effects increase product value only if your customers are willing to pay for them. Otherwise, they increase ink cost without improving margins.

Why the Dowin GT Series UV DTF Deserves Attention

Among commercial UV DTF options, the Dowin GT Series UV DTF printers represent a pragmatic approach that aligns well with real business needs rather than marketing hype.

Practical Strengths of the Dowin GT Series

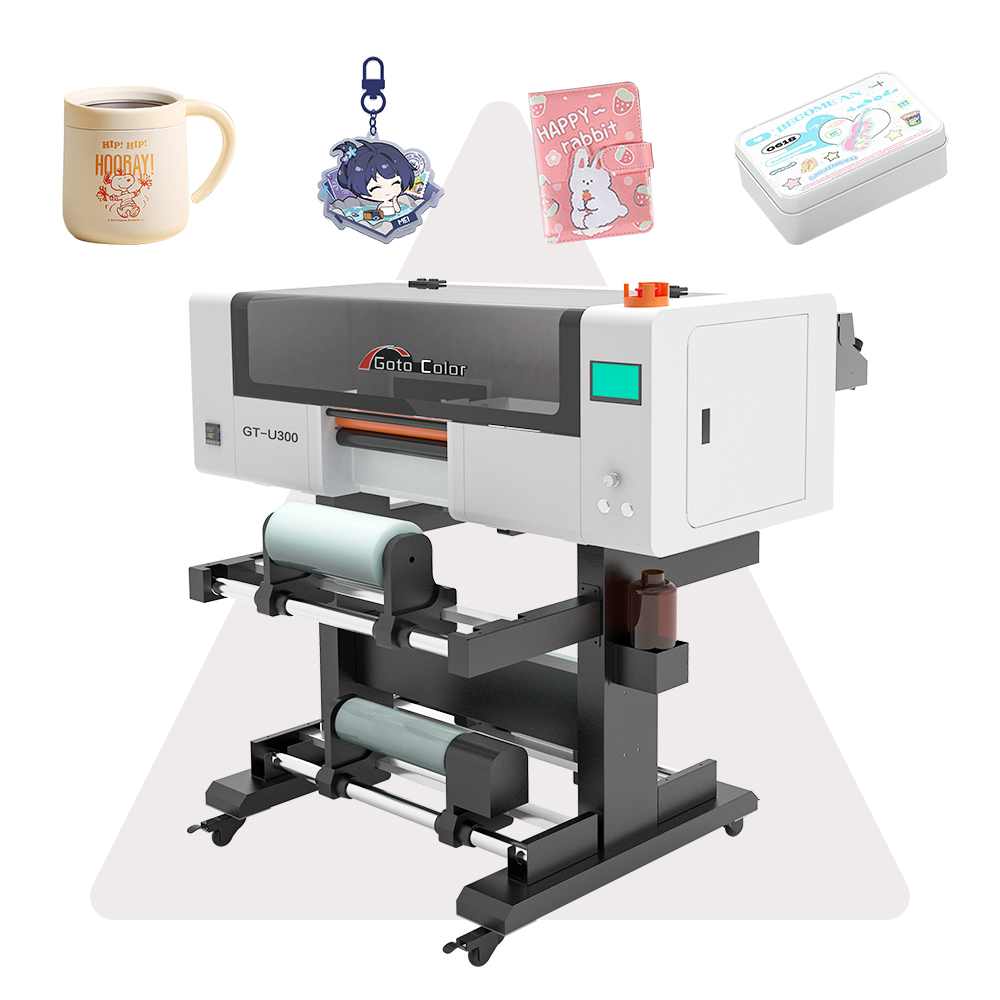

- Multi-format support: Models such as GT-300 and GT-6090 cover both compact and larger working sizes.

- Multi-substrate capability: Suitable for PET film, acrylic, glass, metal, plastic, and wood.

- White ink stability focus: Designed with circulation and agitation systems that reduce sediment-related failures.

- Modular configuration: Businesses can scale without replacing the entire system.

Business Perspective

While some buyers focus heavily on premium brand names, real-world data shows that support accessibility, spare parts availability, and system simplicity often matter more than branding.

The Dowin GT Series fits particularly well for:

- Export-oriented print shops

- Custom signage and label producers

- Businesses balancing budget control with production reliability

Clear opinion:

For many small and mid-sized businesses, a well-supported, configurable system like the Dowin GT Series is a more rational investment than overpaying for prestige hardware with limited local support.

Market Data and User Behavior Trends (2025–2026)

Industry search trends and user discussions show:

- Rising demand for UV DTF over traditional vinyl decals

- Strong adoption in promotional products and signage

- Increasing complaints about poor white ink management in low-end machines

User feedback consistently ranks stability and service above print speed and maximum resolution.

Final Recommendation for 2026 Buyers

If you are selecting a commercial UV DTF printer for 2026, prioritize:

- White ink stability and circulation

- Proven multi-substrate adhesion

- Manageable maintenance workflow

- Reliable technical support

- Clear upgrade path

For most businesses, A3 all-in-one UV DTF printers offer the best balance of cost, output, and risk control. At the same time, systems like the Dowin GT Series UV DTF demonstrate that practical engineering and serviceability can outperform purely brand-driven choices.