An approachable guide with practical opinions for makers and business owners

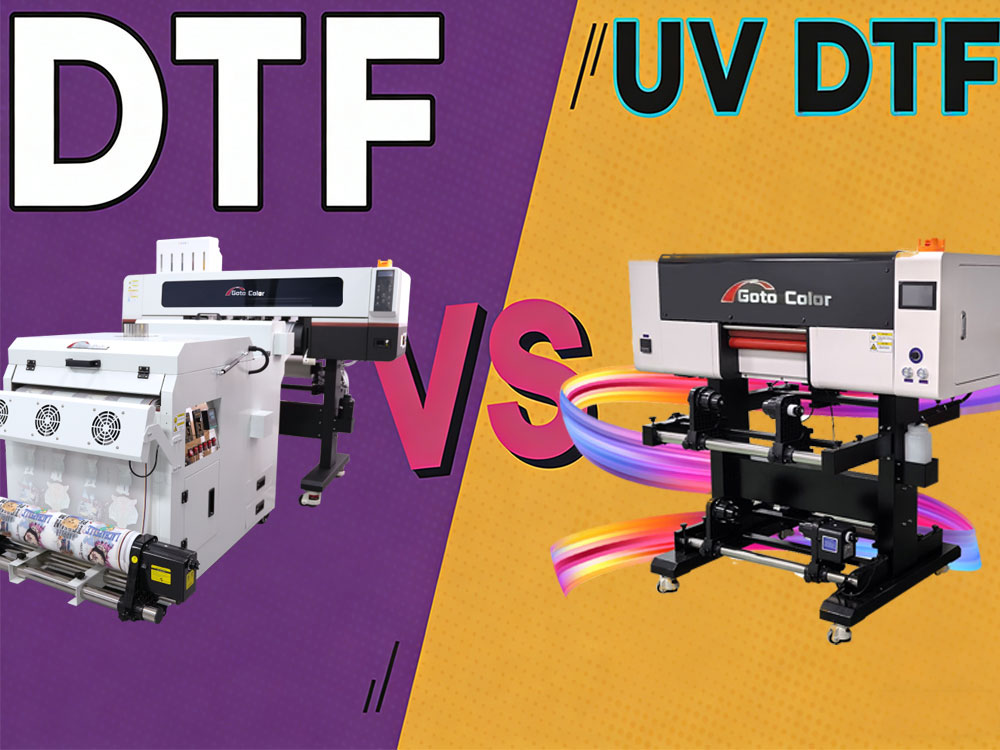

In the world of custom product printing, two technologies that often get compared are traditional DTF printing and UV DTF printing. Superficially they share similarities — both use a film-based transfer approach — but their methods, capabilities, and best use cases are fundamentally different.

Contents

Traditional DTF Printing: Flexible and Fabric-Focused

Direct-to-Film (DTF) printing is a well-established method used mainly for decorating textiles such as t-shirts, hoodies, bags and other soft materials. In this process:

- A design is printed onto a special transparent film using pigment-based inks.

- Adhesive powder is applied while the ink is still wet.

- The powder is heat-activated and cured, bonding it to the film.

- Finally, the film is pressed onto fabric with a heat press.

This results in vibrant, washable prints that stretch with the fabric and maintain good soft feel. Importantly, the print becomes part of the garment’s surface rather than sitting rigidly on top.

Why it matters:

In my view, DTF is an excellent choice for apparel businesses or hobbyists who want durable, wearable graphics without heavy pretreatment or specialized garment printers. Its flexibility and screen-free workflow make short runs convenient.

UV DTF Printing: Hard Surface Customization

UV DTF printing diverges drastically in both technique and application. Instead of pigment inks and heat, this process:

- Prints a design onto a specialized film with UV-curable inks.

- Uses ultraviolet light to instantly cure the inks as they are printed.

- Employs a peel-and-stick approach — the cured design is applied directly to the target surface without a heat press.

The result is a hard, glossy, embossed finish capable of adhering to rigid and non-porous materials like glass, metal, plastic, wood, and acrylic.

Personal insight:

While DTF is essentially a textile solution, UV DTF feels more like a high-end decal or sticker technology. The instant curing and lack of heat press make it more efficient for promotional products and hard goods, but the tactile quality is very different — you lose the soft feel that makes apparel printing appealing.

Side-by-Side Comparison

| Aspect | Traditional DTF | UV DTF |

|---|---|---|

| Ink Technology | Pigment-based (requires adhesive powder) | UV-curable (cured by UV light) |

| Surface Compatibility | Textiles & soft materials | Hard, non-porous surfaces |

| Application Method | Heat press transfer | Peel and stick (no heat) |

| Feel & Finish | Soft, integrated | Glossy, raised, sticker-like |

| Durability | Excellent on fabrics | Excellent on rigid objects but not flexible |

| Workflow Complexity | Multi-step (print → powder → heat) | Simpler and faster print-to-apply |

| Cost | Lower initial cost | Higher cost for UV setup |

Advantages and Limitations

Traditional DTF Printing

Pros:

- Works on nearly all fabric types without pretreatment.

- Produces soft, flexible, washable prints.

- Lower equipment start-up cost than UV DTF.

Cons:

- Not suitable for hard surfaces.

- Requires heat press and careful curing.

UV DTF Printing

Pros:

- Ideal for mugs, bottles, signage, and other rigid items.

- Instant curing and no heat press.

- Durable against scratches and moisture.

Cons:

- Doesn’t bond well with fabrics (not flexible).

- Higher equipment cost and a different expertise set.

Which Should You Use?

The right method depends completely on what you intend to print:

- For custom apparel and fabric goods, traditional DTF printing is clearly superior. Its bonded flexibility and wash resistance are essential for wearables.

- For hard objects and promotional items, UV DTF printing is more efficient and visually striking.

In practice, conflating the two creates unnecessary confusion — they are tools for different jobs and aren’t interchangeable. A common mistake is to imagine that UV DTF could replace classic garment printing; it cannot, because the cured inks and adhesives do not stretch with fabric.

Final Opinion

Both technologies serve distinct markets and excel where they belong. Traditional DTF isn’t obsolete just because UV DTF exists, and vice versa. From my perspective, businesses that diversify into both — with equipment and expertise tailored to each — unlock the most creative and commercial flexibility. Whether you’re printing hoodies or high-end signage, understanding the fundamental technical differences ensures you choose the right method and avoid costly mistakes.